JEFF POWER RAKE

JEFF

JEFF POWER RAKE

The details make the difference of Agrinova machines.

- The metal thickness of the shell

- The types of bearings

- The type of belts

- The type of steel chosen to produce the cutting knives

- Heat treatments to make them as strong and sharp as long as possible and the wide range of types of machines, to meet the specific needs of the lawn to care.

Agrinova knows that every lawn is different and should be treated according to its needs, so the scarifiers that it produce offer a wide variety of cutting systems. The know-how gained over many years of experience and comparison with the gardening sector experts led to the development of different working systems, which allow us to treat with maximum efficiency any kind of lawn.

Scarifier size:38 cm / 45 cm

ROTOR SHAFT WITH MOVABLE/KNIVES

System that allow:• Verticutting: Performs a number of cuts on the ground up to a recommendeddepth of up to 3 cm, but suggest maximun 0,5 cm• Removing the moss by touching the groundThis system is referred floating because even if the impact blades againstsome of the typical gardens obstacle (superficial roots of plants, heads ofsprinklers, curbs, etc ..) Will not be damaged, because they rotate on theirown center and return to their working position thanks to centrifugal forcerising from rotation at 3000 rpm).

SHAFT WITH FIXED BLADES

Verticutting is literally vertical cutting, the operation of creating perfectly preciseand rigid grooves on the grass. Grass roots will be cut off without beingripped off and without damage.The groove will have a constant depth and, if properly registered by the operator,is 0,3 cm to 0,5 cm, perfect far oxygenating the soil.

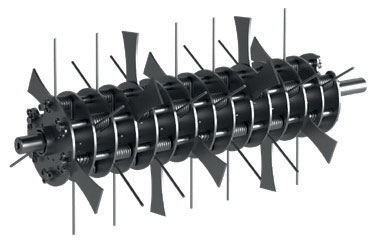

SHAFT WITH SPRINGS AND KNIVES

Often on the lawn there are accumulations of mass and thatch, due to the stagnation of water, tothe constant presence of mass left on the ground using the mulching system. Before grinding thegrass roots and the first layer of soil, it is necessary to clean the thatch sheet. You must comb thegrass layer with soft tips as they are of a spring.However, as a result of a high speed operation, with a considerable amount of power available fromthe engine, it is necessary to give stiffness to the cutting system by spacing the springs with movingknives. This prevents the system from pushing too much on the springs, avoiding the resulting breakage.This type of cutting system requires little power to the engine, and must be performed at thelowest possible speeds.

BELT TRASMISSION

A double toothed belt (for versions from 45 to60 cm).Tension wedge metal belts. mou11ted on doublebeanng far long llfe

RECOILING BAG

Optional

OSCILLATlING FRONT WHEEL AXLE

The cutting system always stays para Ile I o theground (even in slopes)

Easy to move

Good for small cars

TECHNICAL DATA

| JE38R | JE47B2 | ||

|---|---|---|---|

| Working width | 38 cm | 45 cm | |

| Engine | Briggs & Stratton serie E550 | Briggs & Stratton serie 950 | |

| machine code | Cod. JE38R | Cod. JE47B2 | |

| Toothed belts | 1 | 2 | |

| Standar | Shaft with mobile blades 2,5 mm thickness (step 40 mm) | Shaft with mobile blades 2,5 mm thickness (step 40 mm) - Cod. ACO (33 blades) |

|

| Shaft with mobile blades | Shaft with mobile blades | ||

| 2,5 mm thickness (step 30 mm) - Cod. AR1512 | 2,5 mm thickness (step 30 mm) - Cod. AR245 |

||

| Not available | Shaft with mobile blades 1,2 mm thikness (step 40 mm) -Cod. ACOS |

||

| Not available | Shaft with mobile blades 1,2 mm thikness (step 30 mm) - Cod. AR252 |

||

| Working | Shaft with fixed blades | Shaft with fixed blades | |

| system | Optional | 2,5 mm thikness (step 40 mm) - Cod. AR450 (9 coltelli) | 2,5 mm thikness (step 40 mm) - Cod. AR305 (11 coltelli) |

| Optional | Shaft with fixed blades | Shaft with fixed blades | |

| Optional | 2,5 mm thikness (step 30 mm) - Cod. AR450F2 | Shaft with fixed blades 2,5 mm thikness (step 30 mm) - Cod. ACOF2 |

|

| Optional | Not available | Shaft with fixed blades 1,2 mm thikness (step 30 mm) - Cod. ACOF |

|

| Optional | Not available | Shaft with fixed blades 1,2 mm thikness (step 40 mm) - Cod. ACOF1 |

|

| Optional | Not available | Shaft with spring and blades - Cod. AL48 (14 blades / 28 springs) |

|

| Weight | 36,5 kg | 54 kg | |

| Dimensions (box) | 660 x 530 x 630 h cm | 620 x 670 x 660 h cm | |

| General | Dimensions pallet | (with 6 boxes) - 1200 x 800 x 2100 h cm | (with 4 boxes) -1260 x 800 x 1500 h cm |

| information | Bag | Optional (on request) - Cod. AR338 | Optional (on request) - Cod. AR370 |

| Wheels | 4 plastic with ball bearings | 4 plastic with ball bearings |